Overview:Vacuum drying is to heat and dry the material to be dried under vacuum conditions. It uses a vacuum pump to pump air and dehumidify,

Consultingworking principle

The so-called vacuum drying is to heat and dry the dried materials under vacuum conditions. If a vacuum pump is used to extract air and moisture, the drying speed will be accelerated.

Note: If a condenser is used. The solvent in the material can be recovered through the condenser. If the solvent is water, the condenser can be omitted, saving energy investment.

Performance characteristics

◎The boiling point of the material solution decreases under vacuum. Increase the heat transfer driving force of the evaporator. Therefore, the heat transfer area of the evaporator can be saved for a certain amount of heat transfer.

◎The heat source for evaporation operation can be low pressure steam or waste heat steam.

◎The evaporator has less heat loss.

◎It can be disinfected before drying, and there is no impurities in the drying process, which meets GMP requirements.

◎It is a static vacuum dryer. Therefore, the shape of the dried material will not be damaged.

Adapt to materials

Suitable for low-temperature drying of heat-sensitive materials that are easy to decompose, polymerize and deteriorate at high temperatures; it is widely used in the pharmaceutical, chemical, food, and electronics industries.

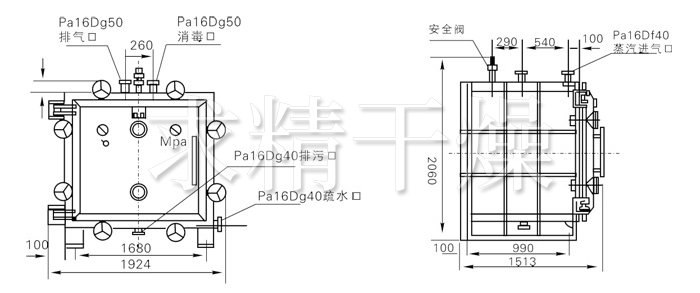

Schematic

Technical specifications

| Name/Specification | FZG-10 | FZG-15 | FZG-20 |

| Inner size of drying box | 1500×1060×1220 | 1500×1400×1220 | 1500×1800×1220 |

| Outer dimensions of drying box | 1513×1924×1720 | 1513×1924×2060 | 1513×1924×2500 |

| Number of drying racks | 5 | 8 | 12 |

| Distance between layers | 122 | 122 | 122 |

| Baking pan size | 460×640×45 | 460×640×45 | 460×640×45 |

| Number of baking trays | 20 | 32 | 48 |

| Make pressure in the drying rack tube | ≤0.784 | ≤0.784 | ≤0.784 |

| Operating temperature of drying rack | 35-150 | 35-150 | 35-150 |

| No-load vacuum in the box | -0.09~0.096 | ||

| At -0.1MPa, heating temperature 110oC, the vaporization rate of water | 7.2 | 7.2 | 7.2 |

| When using condenser, vacuum pump model, power | 2X-70A / 5.5KW | 2X-70A / 5.5KW | 2X-90A / 2KW |

| When the condenser is not used, the vacuum pump model, power | SK-3 / 5.5KW | SK-6 / 11KW | SK-6 / 11KW |

| Drying box weight | 1400 | 2100 | 3200 |

Note: The water ring vacuum pump is combined with mechanical booster to increase the vacuum degree.

download Google

◎When ordering, please choose a suitable vacuum dryer according to factors such as the initial moisture content and final moisture content of the material to be dried, temperature, vacuum, drying capacity and drying time. The same type of vacuum dryer has four heating methods: steam, hot water, heat transfer oil, electric heating. For example, in order to increase the drying capacity, the number of drying racks can be appropriately increased, please submit to our factory in time.

◎The accessories in the vacuum drying system mentioned in the instruction manual can be provided and installed by our factory. Please specify when ordering.

◎The company can provide design, manufacture and installation for the special requirements in the vacuum drying system proposed by users.

◎The company's equipment implements three quality guarantees for users. All accessories are provided for a long time, please rest assured.

Drying equipment is very widely used in industrial testing, and it is necessary to use drying equipment in many fields. Similarly, drying equ…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a large …

ZPG special spray dryer for traditional Chinese medicine extract is a special spray dryer.

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

Belt dryers have a wide range of applications, and they are currently used in pharmaceutical, food, biological, chemical and other fields. Ho…

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…