Overview:The CT-C series hot air circulation oven is equipped with a low-noise, high-temperature-resistant axial flow fan and an automatic temperature control system. The entire circulation system is fully enclosed,

Consultingproduct description

The CT-C series hot air circulation oven is equipped with a low-noise, high-temperature-resistant axial flow fan and an automatic temperature control system. The entire circulation system is fully enclosed, which improves the thermal efficiency of the oven from 3-7% of the traditional oven to the current 35-45% , The thermal efficiency can reach 50%. It saves a lot of energy for our country and improves the economic efficiency of enterprises. In 1990, the National Medical Administration issued the industry standard, and the unified model was RXH.

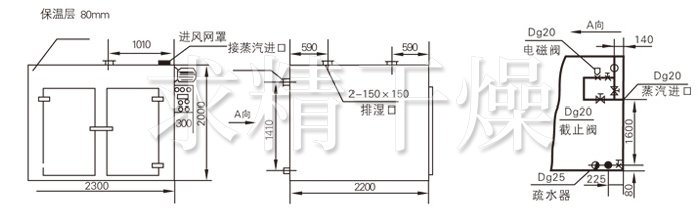

Schematic

◎The heating source has steam, electricity, far-infrared, and electric steam for users to choose;

◎Using temperature: steam heating 50~140oC, up to 150oC;

◎Electricity and far infrared temperature 50~350oC;

◎Automatic control system and computer control system are available for users to choose;

◎The usual steam pressure is 0.02-0.8Mpa (0.2~8kg/m2);

◎ Equipped with electric heating, 15KW calculated according to type I, practical 5-8kw/h;

◎Special requirements shall be stated when ordering;

◎Non-standard oven prices are negotiable;

◎The operating temperature is greater than 140oC or less than 60oC, please specify when ordering;

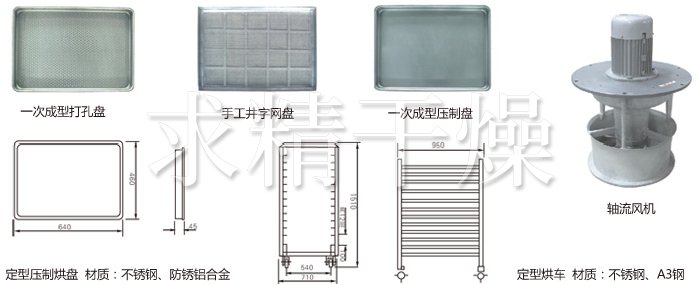

◎The size of the drying car and the baking tray is uniform and interchangeable;

◎Baking pan size: 460×640×45(mm).

Performance characteristics

Most of the hot air circulates in the box, with high thermal efficiency and energy saving. Using the effect of forced ventilation, the box is equipped with an adjustable air distribution plate, the materials are dried evenly, and the heat source can be steam, hot water, electricity, and far infrared, with a wide range of choices. The whole machine has low noise and balanced operation. Automatic temperature control, convenient installation and maintenance. It has a wide range of applications and can dry various materials. It is a universal drying equipment.

Schematic diagram

Technical specifications

| Industry standard model |

technical parameter Model specification |

Dry amount per time (kg) |

Equipped with power (kw) |

Steam consumption (kg/h) |

Cooling area (m2) |

Air volume (m3/h) |

Temperature difference (oC) |

With baking tray |

Dimensions Face width × depth × height |

Supporting drying car | equipment weight |

| RXH-14-B | CT-Ⅰ | 120 | 1.1 | 20 | 20 | 2800 | ±2 | 48 | 2430×1200×2375 | 2 | 1200 |

| RXH-27-B | CT-Ⅱ | 240 | 2.2 | 40 | 40 | 5200 | ±2 | 96 | 2430×2200×2433 | 4 | 1500 |

| RXH-41-B | CT-Ⅲ | 360 | 3 | 60 | 80 | 8000 | ±2 | 144 | 3430×2200×2620 | 6 | 2000 |

| RXH-54-B | CT-Ⅳ | 480 | 4 | 80 | 100 | 9800 | ±2 | 192 | 4460×2200×2620 | 8 | 2300 |

| RXH-5-C | CT-C-O | 25 | 0.45 | 5 | 5 | 3450 | ±2 | 16 | 1130×1100×1750 | 0 | 800 |

| RXH-7-C | CT-C-ⅠA | 50 | 0.45 | 10 | 10 | 3450 | ±2 | 24 | 1400×1200×2000 | 1 | 1000 |

| RXH-14-C | CT-C-Ⅰ | 120 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300×1200×2000 | 2 | 1500 |

| RXH-27-C | CT-C-Ⅱ | 240 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300×2200×2000 | 4 | 1800 |

| RXH-27A-C | CT-C-ⅡA | 240 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 4460×1200×2290 | 4 | 1800 |

| RXH-41-C | CT-C-Ⅲ | 360 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 3430×2200×2000 | 6 | 2200 |

| RXH-42A-C | CT-C-ⅢA | 360 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 2300×3200×2000 | 6 | 2200 |

| RXH-54-C | CT-C-Ⅳ | 480 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4460×2200×2290 | 8 | 2800 |

| RXH-25-A | High-efficiency, high-temperature, far-infrared sterilization oven, power matching according to temperature requirements | 1200×1000×1600 | 1 | 1200 | |||||||

Adapt to materials

Suitable for heating curing, drying and dewatering of materials and products in pharmaceutical, chemical, food, agricultural and sideline products, aquatic products, light industry, heavy industry and other industries. Such as raw materials, crude drugs, Chinese herbal medicines, extracts, powders, granules, granules, water pills, packaging bottles, pigments and dyes, dehydrated vegetables, dried fruits, sausages, plastic resins, electrical components, baking paint, etc.

Accessories Series

Drying equipment is very widely used in industrial testing, and it is necessary to use drying equipment in many fields. Similarly, drying equ…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a large …

ZPG special spray dryer for traditional Chinese medicine extract is a special spray dryer.

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

Belt dryers have a wide range of applications, and they are currently used in pharmaceutical, food, biological, chemical and other fields. Ho…

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…