Overview:The working process of this unit is that the material liquid is input through the diaphragm pump at high pressure, spraying mist-like droplets, and then descending in parallel with the hot air.

Consulting

product description

This unit is a device that can complete drying and granulation at the same time. According to process requirements, the pressure, flow rate and size of nozzle holes of the feed liquid pump can be adjusted to obtain the required spherical particles in a certain size ratio.

The working process of this unit is that the material liquid is input through the diaphragm pump at high pressure, spraying mist-like droplets, and then descending in parallel with the hot air. Most of the powder particles are collected by the discharge port at the bottom of the tower. , The exhaust gas is discharged by the exhaust fan, and the powder is collected by the pollinator at the lower end of the cyclone separator. The outlet of the fan can also be equipped with a secondary dust removal device, and the recovery rate is above 96-98%.

Applications

Features

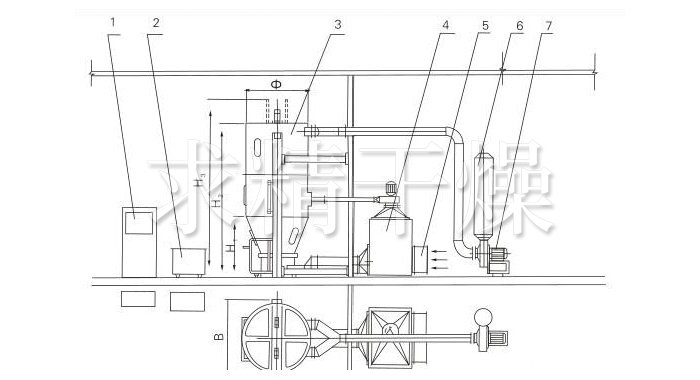

1. Control cabinet 2. Infusion cart 3. Host 4. Heat exchange cabinet 5. Sub-high efficiency filter 6. Muffler 7. Induced draft fan

technical parameter

| Item | Unit/model | PGL-3B | PGL-5B | PGL-10B | PGL-20B | PGL-30B | PGL-80B | PGL-120B | |

| Flow extract | min | kg/h | 2 | 4 | 5 | 10 | 20 | 60 | 100 |

| max | kg/h | 4 | 6 | 15 | 30 | 40 | 100 | 140 | |

| Boiling capacity | min | kg/batch | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

| max | kg/batch | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

| Liquid specific gravity | kg/L | ≤1.30 | |||||||

| Raw material container quantity | L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

| Container diameter | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

| Induced fan power | kw | 3.0 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | |

| Auxiliary fan power | kw | 0.35 | 0.75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

| steam | Consumption | kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

| pressure | Mpa | 0.40-0.60 | |||||||

| Electric heating power | kw | 9 | 15 | 21 | 25.5 | 51.5 | 60 | 75 | |

| Compressed air | Consumption | m3/min | 0.5 | 0.8 | 0.8 | 0.9 | 1.1 | 1.3 | 1.8 |

| pressure | Mpa | 0.40-0.60 | |||||||

| Operating temperature | °C | Room temperature -160°C automatic adjustment | |||||||

| Product moisture | % | ≥0.2 | |||||||

| Material yield | % | ≥99 | |||||||

| Equipment noise | dB | <77 | |||||||

| Host size | Φ | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 |

| H1 | mm | 940 | 1050 | 1070 | 1220 | 1570 | 1590 | 1690 | |

| H2 | mm | 1900 | 2360 | 2680 | 3150 | 3630 | 4120 | 5050 | |

| H3 | mm | 2050 | 2590 | 3020 | 3600 | 4180 | 4770 | 5800 | |

| B | mm | 740 | 890 | 1110 | 1420 | 1620 | 1820 | 2100 | |

Selection example: It is required that the amount of processed extract of each batch I=120kg (solid content is 30%), the amount of seeds II=60kg, and the theoretical finished product amount M=mI+mII=120kgx30%+60kg can be obtained from I and II =96kg, working time T=120kg/30kg/h=4h, the boiling volume can be found in the technical parameter column as the standard load range, so two batches per shift are completed, and the PGL-30 type is more appropriate.

Drying equipment is very widely used in industrial testing, and it is necessary to use drying equipment in many fields. Similarly, drying equ…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a large …

ZPG special spray dryer for traditional Chinese medicine extract is a special spray dryer.

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

Belt dryers have a wide range of applications, and they are currently used in pharmaceutical, food, biological, chemical and other fields. Ho…

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…